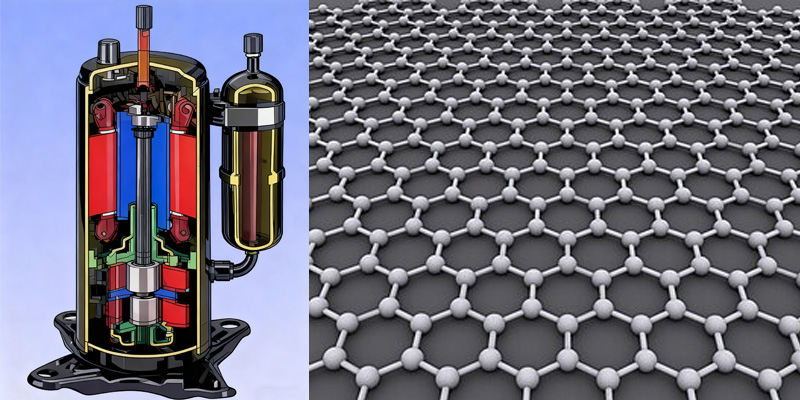

As the development of the air conditioning and heat pump systems is moving toward high efficiency, miniaturization, and intelligent direction, the problem of thermal management inside of the compressor has become increasingly prominent. High-frequency speed, enclosed structures, and high power density—these heating generation challenges are questioning the reliability and lifespan of the compressor.

Among many of the new materials, graphene, with its ultra-high thermal conductivity and excellent mechanical properties, is becoming a new focus in compressor cooling technology.

I. Pain point of compressor heat dissipation

As the heart of the air conditioning systems, the compressor will generate a lot of heat from its components, such as the compression chamber, winding, motor, and power module.

Particularly the compressor for inverter air conditioners, whose frequent speed adjustment and high current density make its heat generation transparent.

If the heat dissipation is poor, it will lead to:

· Motor insulation aging and efficiency decline;

· Deterioration of lubricating oil and exacerbation of friction and wear;

· High cylinder temperature leads to unstable exhaust pressure;

· The electronic control module is overheated and damaged.

The traditional heat dissipation method mainly relies on metal heat conduction and oil/air cooling structure but is limited by thermal conductivity and volume, making it difficult to balance efficient heat dissipation and compact structure.

II. Graphene: A Revolutionary Nanoscale Thermal Conductivity

Graphene, a two-dimensional crystalline material composed of a single layer of carbon atoms, has the following features in thermophysics:

· Its excellent chemical stability and flexibility allow it to be composited with a variety of substrate materials.

· It is ultra-thin and lightweight, enabling efficient heat transfer at micron-level thicknesses;

· Thermal conductivity reaches as high as 5000 W/m·K (compared to approximately 400 W/m·K for copper);

· It possesses both electrical and thermal conductivity, facilitating thermal management in motors and power modules.

· In case of that, graphene is becoming an ideal material for thermal interfaces and heat dissipation enhancers for compressors.

III. The main applications of graphene in compressors

1. Heat dissipation of motor windings and stator

As for the inverter air conditioners, the key factor of the compressors at lower performance is the heating of the motor winding. Adding a graphene composite resin coating to the insulation layer of the winding could improve the thermal conductivity efficiency between the stator and the casing, thus reducing the temperature by 5-10℃. This not only improves motor efficiency (IE level) but also extends insulation lifespan.

2. Thermal interface of electronic control module (PCB/IGBT)

Replacing the traditional silicone grease or aluminum oxide fillers, graphene thermal conductive film is usually adopted between motherboards and the heat sinks, which has lower thermal resistance and better thermal stability. It significantly drops the temperature of the boards in the air conditioners.

3. Heat dissipation enhancement coating for compressor casing

A graphene composite coating can cover the compressor casing surface, forming a high thermal conductivity and radiation heat dissipation composite layer. When operating at high ambient temperature (>45°C), the coating can accelerate the heat release of the shell and prevent the oil temperature from being too high.

4. Lubricant additives and optimization of thermal conductivity

Adding graphene nanoparticles to refrigeration oil has been attempted in some research, aiming to improve the thermal conductivity and wear resistance.

Research shows that oil film has an improved thermal conductivity of 30% and a friction coefficient of 10%.

IV. Technical Challenges and Engineering Breakthroughs

Although graphene has broad application prospects, mass application in compressors still needs time to overcome many challenges:

· Dispersion and interface bonding issues:

Graphene has the feature to aggregate easily, which makes it hard to distribute evenly and necessitates surface modification or composite technology.

· Cost for both provider and consumers:

Graphene materials are more expensive than traditional ones, making it a challenge to balance the performance and cost.

· Stability:

It is unknown whether or not the graphene layer will detach or react in high-temperature, high-pressure, and oil-gas mixed environments. It takes time to proof.

In the future, the compressors will no longer rely on large metal blocks but will be optimized through special materials to achieve micro thermal conductivity. As a new generation of thermal management material, graphene will be combined with AI control and intelligent temperature sensing technology to achieve higher COP and more stable operating conditions for the air conditioning units.

Copyright @ 2026 GUANGZHOU SOUXIN APPLIANCES CO., LTD All Rights Reserved.

Network Supported

Network Supported

Sitemap / Blog / Xml / Privacy Policy

Hi! Click one of our members below to chat on