What is the connecting pipe on the air conditioners?

When installing, many people are concerned about the position of indoor and outdoor units but omit the key part—piping length.

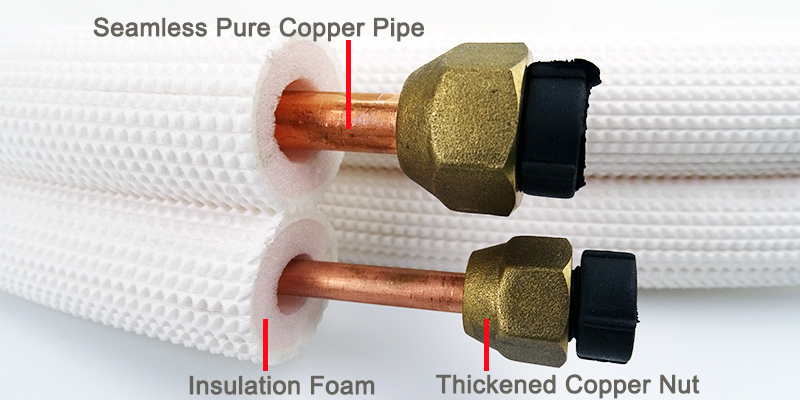

The air conditioner connecting pipe, also known as the refrigerant pipe, usually consists of a copper pipe and insulation. It handles the circulation of the refrigerant between the indoor and outdoor units of the air conditioner. Like the artery of the air conditioning system, once its design is not reasonable, then it will lead to low efficiency, compressor malfunctions, etc.

I. Long piping issues

Lower cooling efficiency

The longer the pipes, the higher the refrigerant flow resistance, which reduces cooling and heating efficiency.

Higher energy consumption

The compressor requires more power to push the refrigerant, significantly increasing the power consumption.

Heavier compressor burden

The long and high-load operation may cause the compressor to overheat or even damage.

More installation difficulty and cost

Longer pipes not only complicate installation but also increase the cost of copper pipes, insulation, and cables.

II. Short piping issues

Limited installation

If the indoor and outdoor units are too close, it will be difficult to arrange the piping, fixing, and heat dissipation.

Noise and vibration

If there is not enough buffer distance, the sound of refrigerant flow will be more obvious, and even the equipment may be damaged due to vibration.

Inconvenient maintenance

If the pipe is too short, the operating space will be limited during future maintenance or relocation, which will increase maintenance costs.

III. How long should the copper pipe be?

It depends on the models of the air conditioner and the installation environment; commonly we recommend the following:

| Horsepower (HP) | Recommended length (M) | The maximum length allowed (M) |

| 1 HP~1.5 HP | 2~3 M | 10~15 M |

| 2 HP~3 HP | 3~5 M | 15~20 M |

| 5 HP and above | 5 M and above | 25~30 M |

Attention: Most air conditioner manufacturers recommend that the connecting pipe should not be less than 3 meters to prevent compressor reverse liquid hammer and avoid problems such as poor refrigerant oil return.

IV. Installation Tips

Use original copper pipes or high-quality refrigerant pipes that meet standards to ensure smooth refrigerant flow.

Ensure complete insulation coverage to prevent energy loss and condensation.

Avoid multiple elbows or sharp bends in the pipes to ensure smooth flow.

If connecting pipes need to be extended, it is recommended to ask a professional and refill it with refrigerant.

Air conditioner connecting pipes should be neither too long nor too short. Proper length is crucial for efficient air conditioning operation. If you're purchasing or installing an air conditioner, be sure to discuss the layout and length of the connecting pipes with your professional installer to avoid unnecessary complications.

For custom designs or large-scale installations, please contact KRG Air Conditioning (souxinaircon). We offer professional product solutions and technical support!

Copyright @ 2026 GUANGZHOU SOUXIN APPLIANCES CO., LTD All Rights Reserved.

Network Supported

Network Supported

Sitemap / Blog / Xml / Privacy Policy

Hi! Click one of our members below to chat on