In coastal areas, islands, and high-salt environments, the air conditioners often face a severe challenge: salt fog corrosion. A quantity of salty particles in the air will attach to the condenser fins, fan motors, electric boxes, and other positions, resulting in oxidation, short circuits, and performance degradation. Is it possible to keep air conditioners working stably for a long time under such harsh environments? Yes, and it will need a systematic salt fog corrosion prevention design.

I. Mechanism of salt fog Damage

Salt fog corrosion is essentially an electrochemical reaction. When salt vapor adsorbs onto a metal surface, an electrolyte film forms, generating a microcurrent between the anode and cathode, accelerating metal oxidation. This is especially true for fins and piping structures made of copper and aluminum. Once corroded, not only will heat transfer capacity decrease, but it can also lead to refrigerant leakage and system failure.

II. Anti-corrosion for key components

1. Protective Coating

· Hydrophilic Coating: Ensuring less condensate and salt accumulation.

· Epoxy Coating: Ensuring a strong barrier for protection that is suitable for highly salty and humid areas.

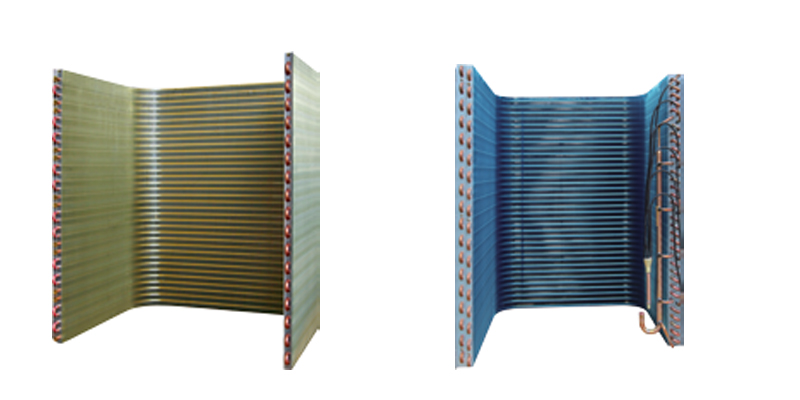

· Golden Fin/Blue Fin Technology: Prolong the lifespan of the condenser by adding an anti-rust layer to the surface of the aluminum fins.

2. Structure protection against corrosion

The chassis and outer casing can be galvanized steel with anti-corrosion spray. And stainless steel or rust-resistant alloy screws and connectors are also considerable for the prevention of rust.

3. Electrical Protection

The electric boxes, circuit boards, and other parts need to be waterproof and sealed with conformal coating, ensuring prolonged operation.

III. System Structure and Drainage Optimization

Salty areas normally come with high humidity. In that case, the drainage and evaporation of condensate become more and more important.

By optimizing the drainage slope, setting individual condensation channels, and installing anti-splashback structures, it is possible to prevent salt from flowing back onto the condenser surface. And additionally adding air filter and protective screen can prevent the sea salt particles getting in.

IV. Test and Certification

Professional air conditioners with salt fog resistance normally pass the tests below:

· ISO 9227 Neutral salt fog Test

· ASTM B117 American Standard

· GB/T 10125 Chinese National Standard

The certificates above demonstrate that the air conditioning units could operate well and withstand the high-salt and high-humidity environment.

The design of salt-fog and corrosion-resistant air conditioners is not only a matter of optimization of materials and coating but more of the comprehensive coordination of the system engineering. From screws to the whole machine, every detail determines the equipment's reliability and stability in harsh environments.

Copyright @ 2026 GUANGZHOU SOUXIN APPLIANCES CO., LTD All Rights Reserved.

Network Supported

Network Supported

Sitemap / Blog / Xml / Privacy Policy

Hi! Click one of our members below to chat on